Hsuan Chang This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Jia-Jan Guo1 1Department of Chemical and Materials Engineering, Tamkang University, Tamsui, Taiwan 251, R.O.C.

Received:

January 3, 2004

Accepted:

May 24, 2004

Publication Date:

December 1, 2005

Download Citation:

||https://doi.org/10.6180/jase.2005.8.4.04

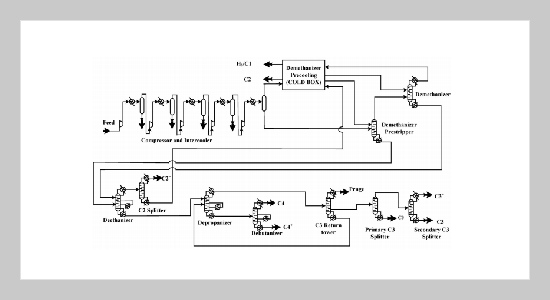

This paper presents the results of applying the dual approach temperature (DAT) method to an industrial ethylene product recovery and separation process. The entire process including the refrigeration system is simulated for extracting process information for heat exchange network design. The sub-ambient operation temperature feature of the process has demonstrated the advantage of DAT method, which allows the use of a smaller heat exchanger approaching temperature relative to a higher network approaching temperature. Comparing the synthesized optimal network to the existing network, the utility consumption and utility cost saving can be reduced by 35.6% and 21.2%, respectively. The payback year for modifying the existing network is only 0.77 year.ABSTRACT

Keywords:

Heat Exchange Network, Dual Approach Temperature, Ethylene Process

REFERENCES