Jium-Ming Lin This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Wen-Jim Tsai1 1School of Mechanical Engineering and Astronautics, Chung-Hua University, Hsinchu, Taiwan 300, R.O.C.

Received:

February 23, 2007

Accepted:

April 16, 2007

Publication Date:

June 1, 2007

Download Citation:

||https://doi.org/10.6180/jase.2007.10.2.03

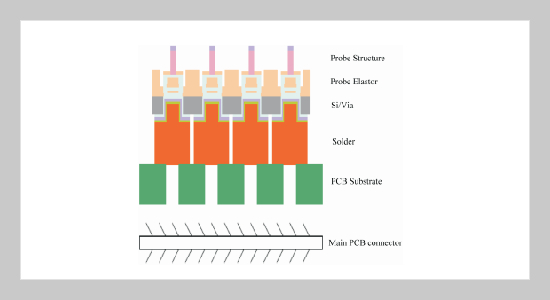

The vertical-type probe card of this paper used Si-wafer as substrate. The key point is to use buffer layers of low k elastomer, such as hydrogen silesquioxane, methyl sequioxane or PI (Polyimide), to release uneven forces due to either non-uniform profile of probe tips and ICs under test by the fabrication processes, or uneven strains and stresses during the burn-in tests. The electrical cross-coupling effects among the very dense probes can also be reduced by using low k elastomer. In addition, it can be applied for wafer level, and Test-During Burn-In (TDBI) to raise the efficiency and performance of test. For tip area as 10 μm x 10 μm, the amount of compression deformation can be obtained as 5.58 μm for 10 grams contact force, which can satisfy the industry specification of 5 μm. By the way it can meet the small requirements of pitch as well as bond pad area as the times go by.ABSTRACT

Keywords:

IC Probe Card, Wafer Level, TDBI, Low k Elastomer

REFERENCES