Meng-Chang Tsai1, Shung-Wen Kang This email address is being protected from spambots. You need JavaScript enabled to view it.2, Heng-Yi Li1 and Wen-Fa Tsai1 1Institute of Nuclear Energy Research, Taoyuan, Taiwan 325, R.O.C.

2Department of Mechanical and Electro-Mechanical Engineering, Tamkang University. Tamsui, Taiwan 251, R.O.C.

Received:

March 20, 2015

Accepted:

July 9, 2015

Publication Date:

September 1, 2015

Download Citation:

||https://doi.org/10.6180/jase.2015.18.3.06

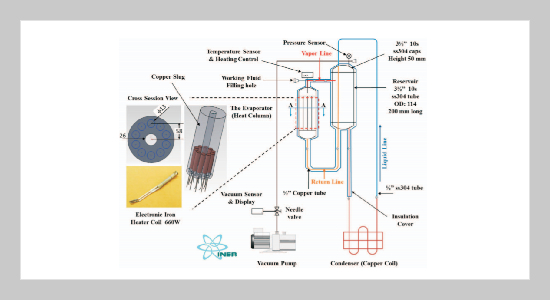

A prototype two-phase reverse-loop thermosyphon (RLT) was fabricated to transport thermal energy downwards to a thermal storage tank. The effect the filling ratio exerted on the thermal performance of the RTL was investigated by conducting experiments that were performed by a range between 47% and 63%. The prototype device comprised an evaporator, a condenser, a reservoir (preheater), and pipes connecting each of the components. The heat transport height was 1500 mm from the evaporator to the bottom of the condenser. Methanol with a concentration of 95% was used as the working fluid. The temperature distribution, temperature difference between the evaporator and condenser, and thermal resistance of the thermosyphon were measured. In addition, a cyclic case, in which the power in coils was alternately switched on and off according to a square wave function was studied. The results indicated that the maximal thermal performance of the RLT occurred when the filling ratio was 60% and the input power was 660 W.ABSTRACT

Keywords:

Reverse-loop, Thermosyphon, Heat Transfer Downward, Cyclic Operation

REFERENCES