Chandrasekhar Udayagiri This email address is being protected from spambots. You need JavaScript enabled to view it.1, Milind Kulkarni2 , Balasubramanian Esakki1 , Sarasu Pakiriswamy1 and Lung-Jieh Yang3 1Vel Tech University, Avadi, Chennai, India

2Engineering Staff College of India, Hyderabad, Telangana, India

3Tamkang University, Tamsui, Taiwan 251, R.O.C.

Received:

September 30, 2015

Accepted:

December 21, 2015

Publication Date:

March 1, 2016

Download Citation:

||https://doi.org/10.6180/jase.2016.19.1.03

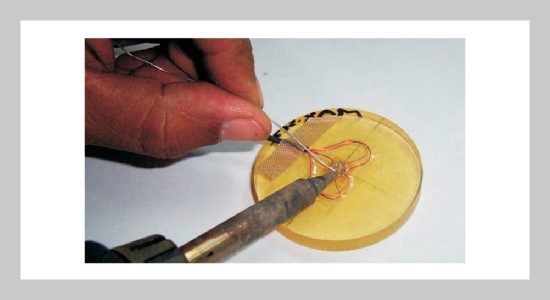

This paper presents the results of exploratory studies for facilitating the direct use of 3D printed parts in design and development of micro aerial vehicles (MAV). 3D printing processes of stereolithography and fused deposition modeling are investigated as the candidate prototyping options. Custom developed electro-chemical and mechanical processes are used to deposit thin structural nickel coatings on 3D printed test specimens and MAV parts. Residual stress and mechanical strength of coated 3D printed specimens are evaluated through experimental methods. Considerable improvement is realized in tensile and impact performance of the coated 3D printed parts. Findings from this study enable the MAV research teams to work with multiple design options and arrive at optimal solutions without severe time and cost penalties that are typically associated with conventional manufacturing procedures.ABSTRACT

Keywords:

Stereolithography, Fused Deposition Modeling, Electro Deposition, Micro Aerial Vehicles, Residual Stress, Design Iteration

REFERENCES