Chi-Yuan Shih This email address is being protected from spambots. You need JavaScript enabled to view it.1, Sue-Huai Gau1 , Chi-Chang Kuo2 , Chang-Yun Huang3 and Sheng-Wei Kuo3 1Department of Water Resources and Environmental Engineering, Tamkang University, Tamsui, Taiwan 251, R.O.C.

2New Century Membrane Co., Ltd, Taichung, Taiwan 407, R.O.C.

3Abontech International Co., Shinchu, Taiwan 300, R.O.C.

Received:

May 15, 2015

Accepted:

October 14, 2015

Publication Date:

March 1, 2016

Download Citation:

||https://doi.org/10.6180/jase.2016.19.1.09

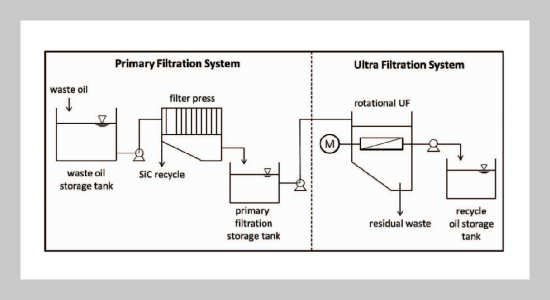

The main problems of recovery cutting oil from spent waste are high viscosity of cutting oil and high content of nano-size particle. This study combined an innovative rotational circular-plate ultrafiltration membrane filter with a scraping device to recycle the cutting oil and remove particles fouling cake attached to the membrane surface, and was able to maintain cutting oil filtrate flux above 6.65 l/m2/hr. Also, the proposed process is the practical solution for materials separation between highly viscosity liquid and fine particles even nano-size. The results show the filtrate of ultrafiltration membrane could meet the reuse requirements of less than 0.03% solid content. Analysis of blended oil characteristics under different blending ratios was conducted, showing the optimum blending ratio of recycled oil to new cutting oil was 6:4. The final production cost can be reduced over 27.4%. The process can achieve waste reuse ratio of greater than 77.2%.ABSTRACT

Keywords:

Rotational Ultrafiltration, Diethylene Glycol, Recycle, Silicon Sawing, Cutting Oil

REFERENCES