Lingchao Xuan This email address is being protected from spambots. You need JavaScript enabled to view it.1, Zhichuan Guan1 and Huaigang Hu1 1School of Petroleum Engineering, China University of Petroleum Huadong, Shandong, P.R. China

Received:

March 2, 2016

Accepted:

June 17, 2016

Publication Date:

March 1, 2017

Download Citation:

||https://doi.org/10.6180/jase.2017.20.1.09

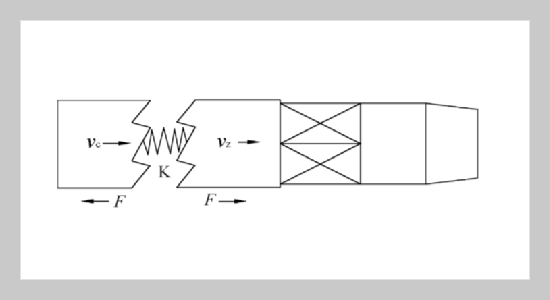

The rotary percussion drilling technology is one of the effective ways to improve the rate of penetration in deep well drilling. The common shortcomings of impact tools used today are the low impact force and the instability of impact frequency. Therefore, a novel rotary percussion drilling tool powered by positive displacement motor was designed. Its principle is that, the PDM drives a hammer piston to rotate, meanwhile the piston hits the anvil to generate impulse load. The dynamic model of this tool shows that, the impact load is influenced by the spring’s storage energy, and the impact time is closely related to the piston’s mass. The impact frequency is the product of the rotary rate of the PDM and the number of piston’s teeth. Experiments showed: the tool’s impact frequency is 25.7~37.6 Hz, and the peak value of impact force is 20~42 kN. The research showed the calculation model has a high accuracy compared with the testing data. The tool’s impact parameters are in range of the optimal value of previous research, and this novel tool has great potential in increasing the ROP in deep well drilling.ABSTRACT

Keywords:

Rotary Percussion, Piston with Teeth, Contact Surface, Impact Force, Dynamic Model, Percussion Test

REFERENCES