Kieu Do Trung Kien1,2 and Nguyen Vu Uyen Nhi2

1Faculty of Materials Technology, Ho Chi Minh City University of Technology (HCMUT), 268 Ly Thuong Kiet Street, Ward 14, District 10, Ho Chi Minh City, Vietnam

2Vietnam National University Ho Chi Minh City, Linh Trung Ward, Thu Duc City, Ho Chi Minh City, Vietnam

Received:

July 3, 2023

Accepted:

September 29, 2024

Publication Date:

November 15, 2024

Copyright The Author(s). This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are cited.

Download Citation: ||https://doi.org/10.6180/jase.202508_28(8).0009

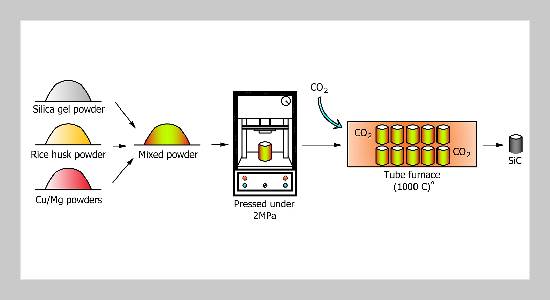

Silicon carbide is a chemical compound known for its high mechanical strength and exceptional thermal resistance. However, its synthesis typically necessitates very high temperatures and involves complex manu facturing techniques. Consequently, numerous studies have sought to lower the synthesis temperature of SiC by employing biomass-derived precursors. Despite these efforts, the efficiency of the SiC synthesis reaction remains low, resulting in suboptimal production yields. This study examines the impact of additives, specifically magnesium and copper, on the formation of SiC . Differential Scanning Calorimetry analysis of the mixtures indicates magnesium additives can facilitate earlier SiC formation compared to copper ( 466.73◦C vs. 522.02◦C ). According to ISO 20068:2008 standards for SiC composition determination, at a sintering temperature of 1000◦C, copper additives are more effective in generating SiC than magnesium. Analysis of SiC composition and X-ray diffraction patterns reveals that magnesium and copper additives significantly enhance the quantity of SiC produced. However, these additives also introduce numerous impurities into the final product. These impurities can be mitigated through acid washing.

Keywords:

Rice husk, silicon carbide, biomass, catalytic

- [1] T. K. K. Do, C. T. Nguyen, and N. M. Huynh, (2024) “Effect of temperature on the ability to synthesize SiC from rice husks" Materials Research Express 11(5): 055510. DOI: 10.1088/2053-1591/ad4981.

- [2] D.Angelova, I. Uzunov, S. Uzunova, A. Gigova, and L. Minchev, (2011) “Kinetics of oil and oil products ad sorption by carbonized rice husks" Chemical Engineer ing Journal 172(1): 306–311. DOI: 10.1016/j.cej.2011.05.114.

- [3] A. Valeeva, A. Gimranova, E. Gottlieb, and E. Gal imov. “Anti-friction epoxy coatings modified with rice husk”. In: IOP Conference Series: Materials Science and Engineering. 971. 3. IOP Publishing. 2020, 032040. DOI: 10.1088/1757-899X/971/3/032040.

- [4] F. Bondioli, L. Barbieri, A. M. Ferrari, and T. Man fredini, (2010) “Characterization of rice husk ash and its recycling as quartz substitute for the production of ceramic glazes" Journal of the American Ceramic So ciety 93(1): 121–126. DOI: 10.1111/j.1551-2916.2009.03337.x.

- [5] Z. Eliaslankaran, N. N. N. Daud, Z. M. Yusoff, and V. Rostami, (2021) “Evaluation of the effects of cement and lime with rice husk ash as an additive on strength behavior of coastal soil" Materials 14(5): 1140. DOI: 10.3390/ma14051140.

- [6] M.Gürü,A.F. Karabulut, M. Y. Aydın, and ˙ I. Bilici, (2015) “Processing of fireproof and high temperature durable particleboard from rice husk" High Tempera ture Materials and Processes 34(6): 599–604. DOI: 10.1515/htmp-2014-0092.

- [7] J.-P. Chen, G. Song, Z. Liu, Q.-Q. Kong, S.-C. Zhang, and C.-M. Chen, (2020) “Preparation of SiC whiskers using graphene and rice husk ash and its photocatalytic property" Journal of Alloys and Compounds 833: 155072. DOI: 10.1016/j.jallcom.2020.155072.

- [8] E. Gorzkowski, S. Qadri, B. Rath, R. Goswami, and J. Caldwell, (2013) “Formation of nanodimensional 3C SiC structures from rice husks" Journal of electronic materials 42: 799–804. DOI: 10.1007/s11664-012-2421y.

- [9] Z. Chen, Z. Wu, J. Su, J. Li, B. Gao, J. Fu, X. Zhang, K. Huo,andP.K.Chu,(2021) “Large-scale and low-cost synthesis of in situ generated SiC/C nano-composites from rice husks for advanced electromagnetic wave absorption applications" Surface and Coatings Technology 406: 126641. DOI: 10.1016/j.surfcoat.2020.126641.

- [10] S. I. Maximenko, J. A. Freitas, P. B. Klein, A. Shri vastava, and T. S. Sudarshan, (2009) “Cathodolumines cence study of the properties of stacking faults in 4H-SiC homoepitaxial layers" Applied Physics Letters 94(9): DOI: 10.1063/1.3089231.

- [11] Y. L. Chiew and K. Y. Cheong, (2011) “A review on the synthesis of SiC from plant-based biomasses" Materials Science and Engineering: B 176(13): 951–964. DOI: 10.1016/j.mseb.2011.05.037.

- [12] T. Van Khai, H. N. Minh, N. V. U. Nhi, K. D. T. Kien, et al., (2021) “Effect of composition on the ability to form SiC/SiO2-C composite from rice husk and silica gel" Jour nal of Ceramic Processing Research 22(2): 246–251. DOI: 10.36410/jcpr.2021.22.2.246.

- [13] S. Moustafa, M. Morsi, and A. A. El-Din, (1997) “For mation of silicon carbide from rice hulls" Canadian met allurgical quarterly 36(5): 355–358. DOI: 10.1179/cmq.1997.36.5.355.

- [14] R. V. Krishnarao and Y. R. Mahajan, (1995) “Effect of acid treatment on the formation of SiC whiskers from raw rice husks" Journal of the European Ceramic Society 15(12): 1229–1234. DOI: 10.1016/0955-2219(95)00097-6.

- [15] B. B. Nayak, B. C. Mohanty, and S. K. Singh, (1996) “Synthesis of silicon carbide from rice husk in a dc arc plasma reactor" Journal of the American Ceramic Society 79(5): 1197–1200. DOI: 10.1111/j.1151-2916.1996.tb08572.x.

- [16] L. Sun and K. Gong, (2001) “Silicon-based materials from rice husks and their applications" Industrial & engineering chemistry research 40(25): 5861–5877. DOI: 10.1021/ie010284b.

- [17] H. Liang, J. Lu, Q. Yan, and T. Song, (2018) “Chemical catalysts of Fenton reaction for single-crystal SiC based on nanoindentation" International Journal of Abrasive Technology 8(3): 232–244. DOI: 10.1504/IJAT.2018.094171.

- [18] K.Janghorban and H.Tazesh, (1999) “Effect of catalyst and process parameters on the production of silicon carbide from rice hulls" Ceramics international 25(1): 7–12. DOI: 10.1016/S0272-8842(97)00077-1.

- [19] Y. Shi, F. Zhang, Y.-S. Hu, X. Sun, Y. Zhang, H. I. Lee, L. Chen, and G. D. Stucky, (2010) “Low-temperature pseudomorphic transformation of ordered hierarchical macro-mesoporous SiO2/C nanocomposite to SiC via magnesiothermic reduction" Journal of the American Chemical Society 132(16): 5552–5553. DOI: 10.1021/ja1001136.

- [20] F. Narciso-Romero and F. Rodriguez-Reinoso, (1996) “Synthesis of SiC from rice husks catalysed by iron, cobalt or nickel" Journal of materials science 31(3): 779–784. DOI: 10.1007/BF00367899.

- [21] S.-C. Kim, M.-T. Kim, S. Lee, H. Chung, and J.-H. Ahn, (2005) “Effects of copper addition on the sintering behavior and mechanical properties of powder processed Al/SiC p composites" Journal of materials science 40: 441–447. DOI: 10.1007/s10853-005-6101-7.

- [22] C. E. Bronnimann, R. C. Zeigler, and G. E. Maciel, (1988) “Proton NMR study of dehydration of the silica gel surface" Journal of the American Chemical Society 110(7): 2023–2026. DOI: 10.1021/ja00215a001.

- [23] A. Saberi, B. Alinejad, Z. Negahdari, F. Kazemi, and A. Almasi, (2007) “A novel method to low tempera ture synthesis of nanocrystalline forsterite" Materials Research Bulletin 42(4): 666–673. DOI: 10.1016/j.materresbull.2006.07.020.

- [24] Y. Chunmiao, Y. Lifu, L. Chang, L. Gang, and Z. Shengjun, (2013) “Thermal analysis of magnesium re actions with nitrogen/oxygen gas mixtures" Journal of hazardous materials 260: 707–714. DOI: 10.1016/j.jhazmat.2013.06.047.

- [25] W. Liu, B. Jiang, S. Luo, S. Chen, and F. Pan, (2018) “Mechanical properties and failure behavior of AZ61 mag nesium alloy at high temperatures" Journal of materials science 53: 8536–8544. DOI: 10.1007/s10853-018-2125-7.

- [26] V. V. Pujar and J. D. Cawley, (1995) “Effect of stacking faults on the X-ray diffraction profiles of β-SiC powders" Journal of the American Ceramic Society 78(3): 774 782. DOI: 10.1111/j.1151-2916.1995.tb08246.x.

- [27] B.-S. Sung andY.-H. Yun, (2017) “SiC Conversion Coat ing Prepared from Silica-Graphite Reaction" Advances in Materials Science and Engineering 2017(1): 6383084. DOI: 10.1155/2017/6383084.

- [28] C. S. Ferreira, P. L. Santos, J. A. Bonacin, R. R. Pas sos, and L. A. Pocrifka, (2015) “Rice husk reuse in the preparation of SnO2/SiO2Nanocomposite" Materials Research 18(3): 639–643. DOI: 10.1590/1516-1439.009015.

- [29] A. M. EL-Rafei, (2022) “Preparation and characteri zation of mesoporous amorphous nano-silica and nano cristobalite for value enhancement of low-cost Egyp tian waste materials" Ceramics International 48(21): 32185–32195. DOI: 10.1016/j.ceramint.2022.07.160.

- [30] K. D. T. Kien et al., (2023) “Effect of the sintering tem perature on the carbonization behaviour of woodceramics from the cashew nut shell waste" Journal of Ceramic Processing Research 24(1): 127–133. DOI: 10.36410/jcpr.2023.24.1.127.

- [31] R. Phul, C. Kaur, U. Farooq, and T. Ahmad, (2018) “Ascorbic acid assisted synthesis, characterization and cat alytic application of copper nanoparticles" Mater. Sci. Eng. Int. J 2(4): 90–94. DOI: 10.15406/mseij.2018.02.00040.

- [32] M.Kouti and L. Matouri, (2010) “Fabrication of nano sized cuprous oxide using fehling’s solution":

- [33] C. Ashok, K. V. Rao, and C. S. Chakra, (2014) “Struc tural analysis of CuO nanomaterials prepared by novel microwave assisted method" Journal of Atoms and Molecules 4(5): 803–806.

- [34] S. Xu, M. E. Ikpi, J. Dong, J. Wei, W. Ke, and N. Chen, (2012) “Effects of Cadmium alloying on the Corrosion and Mechanical Properties of Magnesium" International Journal of Electrochemical Science 7(5): 4735–4755. DOI: 10.1016/S1452-3981(23)19578-2.

- [35] F. Zhang, Q. Meng, W. Fan, S. Chen, and D. Zhang, (2012) “Preparation of Mg2Si based thermoelectric nano materials by low-temperature reaction" Procedia Engi neering 27: 200–205. DOI: 10.1016/j.proeng.2011.12. 444.

- [36] S. Durdu, A. Aytac, and M. Usta, (2011) “Charac terization and corrosion behavior of ceramic coating on magnesium by micro-arc oxidation" Journal of Alloys and Compounds509(34): 8601–8606. DOI: 10.1016/j.jallcom.2011.06.059.

- [37] T. Chanadee, (2017) “Experimental studies on self propagating high-temperature synthesis of Si-SiC com posite from reactants of SiO2 derived from corn cob ash/C/Mg" Journal of the Australian Ceramic So ciety 53(1): 245–252. DOI: 10.1007/s41779-017-0030-1.

- [38] A. Nomoev, V. Lygdenov, V. Mankhirov, E. Khar taeva, and V. Syzrantsev. “Porous silicon obtained by the metallic thermal reduction of high-purity silica gel”. In: IOP Conference Series: Materials Science and Engineering. 1000. 1. IOP Publishing. 2020, 012009. DOI: 10.1088/1757-899X/1000/1/012009.